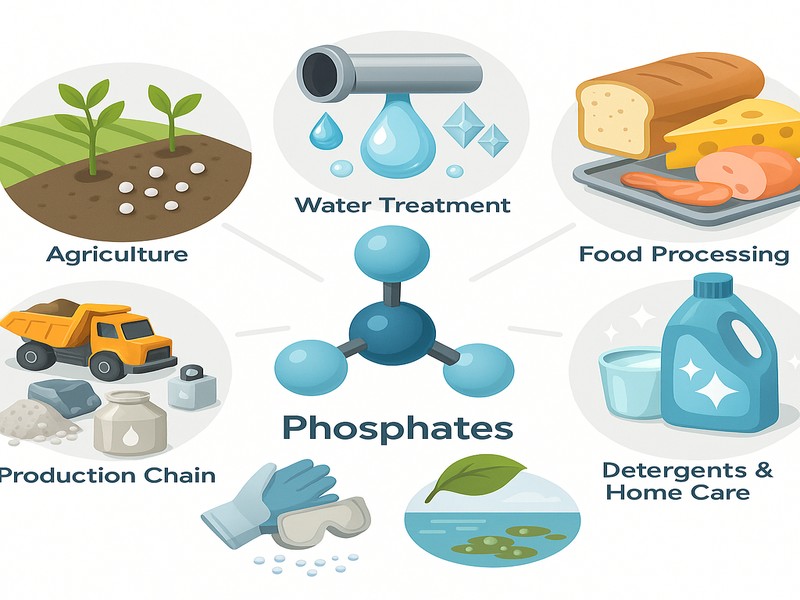

Phosphates sit at the intersection of agriculture, water treatment, food processing, home & personal care, ceramics, and even battery materials. In industry, “phosphates” refers to a broad family of phosphorus-containing compounds—from simple orthophosphate salts and phosphoric acid to ammonium phosphates (MAP/DAP) and condensed/polyphosphates such as STPP and SHMP.

What are Phosphates?

“Phosphates” is the umbrella term for phosphorus-containing inorganic chemicals built around the phosphate anion. The simplest unit is orthophosphate (PO₄³⁻). Link two orthophosphates and you get pyrophosphate; link many to form polyphosphates (including metaphosphates and tripolyphosphate).

Pair phosphate with different cations and you obtain families such as ammonium phosphates (e.g., MAP, DAP), alkali phosphates (sodium, potassium), and alkaline-earth phosphates (calcium, magnesium). Industrially, most phosphates originate from phosphate rock, which is mined, upgraded, and converted to phosphoric acid and downstream salts.

Key properties

Because “phosphates” is a family rather than a single chemical, properties vary. Still, several shared traits guide handling and formulation:

- High water affinity: Most alkali metal and ammonium orthophosphates are readily water-soluble; many condensed phosphates are also highly soluble and sequester hardness ions (Ca²⁺/Mg²⁺).

- Buffering action: Orthophosphate/hydrogen phosphate/dihydrogen phosphate pairs provide excellent buffering around pH ~6–8.

- Corrosion inhibition & sequestration: Polyphosphates (e.g., sodium hexametaphosphate, SHMP) bind metal ions and disperse particulates, aiding scale control and metal passivation in water systems.

- Nutrient source: Ammonium phosphates (DAP/MAP) and calcium phosphates deliver plant-available phosphorus.

- Food-grade functionality: A wide set of phosphate additives—E339–E341, E450–E452—serve as leavening agents, emulsifiers, stabilizers, water binders, and sequestrants in foods and beverages.

Common Commercial Forms

| Family / Product | Typical Formula | P Content (as P₂O₅, %) | Solubility (20 °C) | Typical pH in Solution | Primary Uses | Regulatory Notes |

| Phosphoric acid | H₃PO₄ | ~54 (in 85% acid) | Miscible | Acidic (~1–2) | Fertilizer intermediate; metal treatment; pH control | Food, technical, and electronic grades are widely available. |

| MAP (monoammonium phosphate) | NH₄H₂PO₄ | ~52 (typical) | High | Slightly acidic | Fertilizer, fire retardants, and crystals in optics | Soil zone becomes acidic vs. DAP—relevant in calcareous soils. |

| DAP (diammonium phosphate) | (NH₄)₂HPO₄ | 46 (common 18-46-0) | 588 g/L | Slightly alkaline (7.5–8) | Fertilizer, yeast nutrient, fire retardants | Alkaline micro-zone on dissolution; may impact seed placement. |

| STPP (sodium tripolyphosphate) | Na₅P₃O₁₀ | — | High | Alkaline | Detergent builder; food water-binding (seafood/meat) | FDA GRAS when used per GMP; food-grade specs apply. |

| SHMP (sodium hexametaphosphate) | (NaPO₃)₆ (avg.) | — | High | Slightly acidic to neutral | Water softening, sequestration; food texture/color retention | Also used in dairy/processed cheeses; polymerization degree matters. |

| Calcium phosphate (tri-, di-) | Ca₃(PO₄)₂ / CaHPO₄ | — | Low–moderate | Slightly basic | Mineral supplement; antacid; ceramics, glass | Food/pharma grades common; insoluble forms add opacity/whitening. |

Physical Forms & Grades you’ll Encounter

Liquids: Phosphoric acid solutions (often 75–85%); liquid polyphosphate blends for water treatment dosing.

Crystals / granules: DAP/MAP for fertilizer blending; crystalline monobasic/dibasic/tribasic sodium or potassium phosphates.

Powders / beads / glassy solids: STPP and SHMP (the latter is made by condensing/annealing sodium phosphates and rapidly cooling to preserve chain length). Food, technical, and industrial grades differ in heavy-metal limits, loss on drying, polymerization degree, and microbiological specs.

How Phosphates are Produced

From rock to phosphoric acid (the “wet process”)

Industrial phosphate chemistry starts with phosphate rock—primarily the mineral apatite—mined, beneficiated, and digested with sulfuric acid to make wet-process phosphoric acid (WPA). In the dihydrate route, the core reaction is often summarized (for hydroxyapatite or fluorapatite) as:

Ca5(PO4)3OH+5H2SO4→3H3PO4+5CaSO4+H2O

Ca5(PO4)3F+5H2SO4→3H3PO4+5CaSO4+HF

Gypsum (CaSO₄·2H₂O) is the principal by-product. Process variants (hemi-/dihydrate or double-hydrate) tune filtration rates, acid strength, and gypsum morphology.

Supply context: In 2024, the U.S. produced ~20 million tons of marketable phosphate rock, reflecting a concentrated global supply chain where a few regions dominate reserves and exports. These upstream realities cascade into downstream phosphate derivatives.

Neutralization to make salts

Reacting WPA (or high-purity furnace-process acid where required) with bases such as ammonia, sodium carbonate/caustic, or lime yields ammonium phosphates (MAP/DAP), sodium phosphates (mono-, di-, tribasic), and calcium/magnesium phosphates. Granulation, crystallization, or spray-drying shapes the final form.

Condensation to polyphosphates

Heating selected sodium phosphate mixes dehydrates and polymerizes orthophosphates into pyro- and metaphosphate chains/rings (e.g., SHMP). Composition and cooling rate control average chain length and performance in sequestration and dispersion. Industrial methods range from single-stage melts to two-step routes via sodium acid pyrophosphate.

Typical Applications by Sector

Agriculture & horticulture

DAP/MAP are high-analysis, rapidly soluble fertilizers delivering plant-available P (and N from ammonium). DAP often raises the local pH around granules; MAP tends to acidify that micro-zone—relevant for seed safety and high-pH soils.

Calcium phosphates augment animal feeds and soil amendments.

Water treatment & infrastructure

Polyphosphates condition feedwater, chelate hardness ions, and help control corrosion/scale in potable and industrial water systems; blends with orthophosphate are common in municipal corrosion control programs.

Home & personal care/detergents

STPP and related builders raise alkalinity, sequester ions, and boost surfactant performance. Note: many jurisdictions restrict consumer detergent phosphorus to curb eutrophication (see “Regulatory landscape”).

Food & beverage processing

Food-grade phosphates (E-numbers E339–E341, E450–E452) serve as leavening acids/bases, emulsifiers, melt salts (cheese), moisture retainers (seafood/meat), and beverage tartness modifiers. Selection depends on pH target, ionic strength, and label goals.

Industrial & materials

Metal finishing (phosphating) improves paint adhesion and corrosion resistance; ceramics/glass use calcium phosphates for opacification; fire retardants draw on ammonium phosphates; and energy storage taps phosphate-based cathode materials (e.g., LFP), though those are specialized beyond commodity phosphates.

Safety & Handling

Hazard profile varies: Orthophosphate salts typically present low acute toxicity but can irritate eyes/skin; phosphoric acid is corrosive; and phosphate dusts can cause respiratory irritation—consult each product’s SDS.

Recommended practices

- PPE: Safety glasses/face shield, gloves compatible with acids/alkalis, and dust control (local exhaust) where powders are handled.

- Storage: Keep dry, sealed, and away from moisture for polyphosphates (they can hydrolyze); segregate acids from bases.

- Mixing/dilution:Always add acid to water when preparing phosphoric acid solutions.

- First aid: Immediate eye/skin flushing for splashes; seek medical advice after significant exposure. (Follow SDS-specific guidance.)

Transportation & Packaging

Liquids: Phosphoric acid moves in lined tankers/ISO tanks; corrosion-resistant materials (e.g., specific stainless steels, lined carbon steel) are typical.

Solids: DAP/MAP are shipped as granules in bulk bags or bulk rail/sea; STPP/SHMP ship in lined bags/drums to limit moisture pickup.

Compliance: Many phosphate salts are not DOT “hazardous materials,” but phosphoric acid is regulated as a corrosive—use the proper UN identification and local rules.

Environmental Impacts & How to Mitigate Them

The central environmental concern is nutrient pollution: phosphorus run-off fuels algal blooms and eutrophication, degrading water quality and ecosystems. Industrial and agricultural stakeholders mitigate this through nutrient management, precision application, and advanced wastewater phosphorus removal (chemical precipitation, biological P removal).

Regulatory landscape (detergents & consumer products)

To reduce phosphorus loading, the EU limits phosphates in consumer laundry and automatic dishwasher detergents, effectively phasing out high-phosphate formulations in these categories; many regions/states in the U.S. pursued similar restrictions. If you formulate consumer detergents, ensure compliance with the applicable phosphorus caps.

Food-grade usage

Food phosphates are widely permitted as additives (E-numbered) with good manufacturing practice and purity constraints; selection must align with regional additive lists and category-specific limits. Check the latest authority lists when exporting.

Why do Phosphate Prices Move?

You won’t find a single “phosphate price”—markets span phosphate rock, phosphoric acid, MAP/DAP, and specialty polyphosphates. Broadly, costs move with:

- Upstream rock supply & mining concentration (few regions dominate reserves and exports).

- Sulfur (for sulfuric acid) and ammonia pricing—key inputs into WPA and ammonium phosphates.

- Energy and logistics costs (power-intensive operations; long-haul bulk shipments).

- Regulatory & trade dynamics (export controls, tariffs, environmental rules).

- Agricultural demand cycles tied to planting seasons and global crop economics.

For evidence-based context, consult the USGS Mineral Commodity Summaries and the USGS phosphate rock data sheets, which track production, reserves, and market structure annually.

MAP vs DAP: Which to Choose?

Both are excellent P sources; the choice often hinges on soil chemistry, crop, and application method.

| Attribute | MAP | DAP |

| Chemical | NH₄H₂PO₄ | (NH₄)₂HPO₄ |

| Typical grade | 11-52-0 to 12-52-0 (varies) | 18-46-0 |

| Dissolution micro-pH | Acidic micro-zone | Alkaline micro-zone |

| Seed safety | Generally safer in seed row on alkaline soils | More caution near seed (ammonia / pH spike) |

| Common uses | Dryland cropping, cotton (select regions) | Broadacre blends; sugarcane, horticulture, pastures |

| Notes | Can offset calcareous soils | High solubility; quick P and N availability |

Evidence for these agronomic differences comes from agricultural extension resources and manufacturer fact sheets. Always validate under local agronomy conditions.

Quality & Specifications to Request When Buying

When you request quotations or samples, specifying the right metrics up front speeds qualification:

Grade & application: Technical, food, or pharma; or fertilizer grade (MAP/DAP granule size distribution).

Assay: Total phosphate (often as % P₂O₅ for fertilizers) or product purity (% as supplied).

Impurities / heavy metals: As, Pb, Cd, Hg, and fluoride (key for WPA derivatives).

Functional parameters:

- Polyphosphates: average chain length (n), sequestration capacity, complexing value, solution clarity, pH.

- Food: compliance with E-number authorization; confirm regional limits and intended use categories.

- Fertilizers: granule hardness, particle size (SGN), caking behavior, water solubility, dusting index.

Physical form & packaging: bags (with liners), bulk bags, liquid totes/ISO; moisture protection for polyphosphates.

Documentation: COA, SDS, HACCP/FSSC/ISO certifications (where applicable), and compliance statements (e.g., detergent phosphorus limits for retail formulas in restricted markets).

Storage & Shelf life

Keep dry: Polyphosphates slowly hydrolyze to shorter chains/orthophosphate in humid conditions—store in sealed packaging below recommended RH/temperature.

Avoid cross-contamination: Separate acids from alkalis, oxidizers, and materials sensitive to pH or chelation.

Rotate stock: Observe FIFO, especially for powdered builders and food-grade materials where functionality (e.g., sequestration or leavening behavior) can drift with time.

Practical Buying Channels

Direct from manufacturers of fertilizers or condensed phosphates for large, repeat volumes.

Regional distributors for multi-SKU portfolios (food-grade, water-treatment, detergent builders) and just-in-time deliveries.

Contract tolling where you need custom blends (e.g., orthophosphate/polyphosphate ratios for water programs; tailored food phosphate blends).